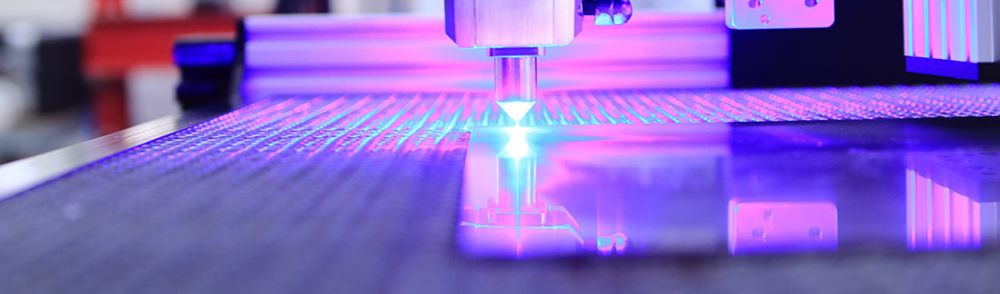

Fiber laser cutting system uses laser light emitted from the laser and focused into a high power density laser beam, which illuminates the surface of the workpiece, enabling the workpiece to instantly reach the melting point or boiling point. Fiber laser cutting machine is known for its excellent beam quality, extremely high stability, low heat generation and less thermal damage to workpiece, particularly suitable for processing carbon steel, copper, galvanized steel and more metal materials, as well as for cutting ultra-thin or small complex geometric parts.

High cutting precision: a standard model of our fiber laser cutting machine features positioning accuracy of 0.05mm, and repositioning accuracy of 0.03mm.

Narrow kerf width: fiber laser is able to emit extremely small focal spot to give very high power intensity which enables melting of the workpiece at the laser-material interaction zone at a high speed. The relative movement between laser beam and workpiece leads to small kerf formation, the kerf width is generally within a range of 0.10-0.20mm.

Smooth cutting surface: fiber laser cutting machine can attain a virtually burr-free cutting surface, and the achievable surface roughness can be controlled within Ra6.5.

High cutting speed: taking 1500W fiber laser cutting machine as an example, when it cuts a carbon steel sheet of 2mm in thickness, the cutting speed can reach 10m/min and the positioning speed is up to 30m/min. The cutting speed of fiber laser cutter is much faster than that of wire cutting machine.

Premium cutting quality: non-contact cutting means no degradation in cut quality, small heat affected zone and nearly no thermal deformation, avoiding cutting defects like edge collapse that are usually occur in shearing process. The cut kerf produced by fiber laser cutting does not need for secondary processing.

No damage to workpiece: thanks to that the laser cutting head does not touch the workpiece surface, fiber laser cutting will not cause any scratches on the workpiece.

High versatility and flexibility: with its features of high flexibility, fiber laser cutting machine is able to process workpieces with any shape, and capable of cutting metal tubes and profiles.

Multiple processable materials: fiber laser cutting machine can process cold rolled steel, low/medium carbon steel, stainless steel, aluminum alloy, galvanized steel, brass, etc.

No need for molds: laser cutting eliminates the need for molds, this helps users reduce mold cost and time for mold changing or repairing, which translate to better productivity while lowering production cost, primarily suited for processing large-sized workpiece.

Optimized material usage: through computer programming, multiple products of various shapes can be cut with optimal material usage.

Rapid prototyping: fiber laser cutting machine can help metal fabricator rapid metal prototyping to create new products on the shortest timeline.

Eco-friendly: laser cutting process produces less waste and low noise level, resulting in a clean, safe and contamination-free manufacturing environment.

Laser Source

Laser source used in our fiber laser equipment is from Maxphotonics, a domestically leading laser manufacturer, featuring extremely high laser beam quality and reliability, excellent energy density, high electro-optical conversion efficiency, and low maintenance cost.

- Electro-optical conversion efficiency: >25%

- Power: 10%-105%

- Laser beam: BPP<2.5

- Pump source service life: 100,000h

Laser Cutting Head

Drift-free, fast-reacting distance measurement

Permanent protective glass observation window

Dust-proof optical path

LED operating status display

Display of operating parameters via Bluetooth and interface for machine control

Monitoring cutting nozzle (cutting gas) and gas pressure

Lightweight and slim design, providing fast acceleration and cutting speed

JUNYI fiber laser equipment adopts CypCut control system which is characterized by high integration, complete function and ease of use, it is extensively used in laser cutting equipment.

Exceptional gas pressure adjustment: gas pressure can be easily adjusted via operating interface to guarantee the consistency of cutting parameters.

Laser power control: CypCut laser cutting control system can independently control the open/close of shutter so that laser power generated from laser can be controlled to accommodate various metal materials with different thicknesses, cutting speed and cutting gas, therefore creating a uniform cut effect without any burn marks. This CypCut system allows user to continue the processing from the position where it stopped last time.

Automatic edge seeking: this function helps user find the edges and inclination angle of the metal sheet.

Frog jump lifting: able to set up the height of cutting head by selecting the graphics of cutting.

S-shaped acceleration and deceleration: CypCut laser cutting control system can control the changes in the speed by acceleration and deceleration to efficiently achieve better processing effect without overcut or burn marks.

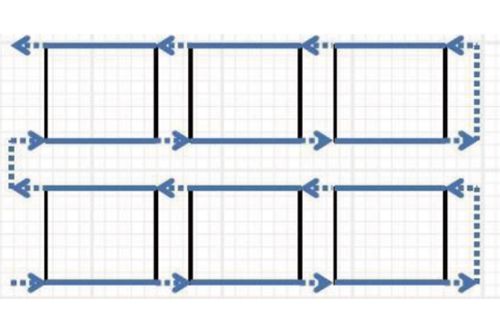

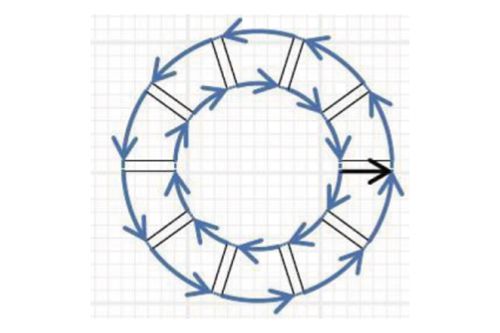

Fly cutting: scanning is applied to both straight line and arc cutting paths to maximize the material utilization rate, thus greatly reducing material waste while yielding a higher profit.

Straight line scan

Straight line scan Arc and circle scan

Arc and circle scan

Cutting compensation: CypCut system has the functions of pitch compensation for mechanic error including backlash, thus improving the processing precision of the laser cutting machine.

Explore our models below to find more information on the fiber laser cutting machine of your interest:

VF3015, VS3015, VF3015H, VF6025H, VF60G