With the increasing variety of kitchenware from metal kitchen cabinets, metal hoods to small metal cookware, it is important for kitchenware manufacturers to choose reliable and efficient metal processing equipment. Fiber laser cutting machine is an ideal solution specifically for metal kitchenware manufacturing.

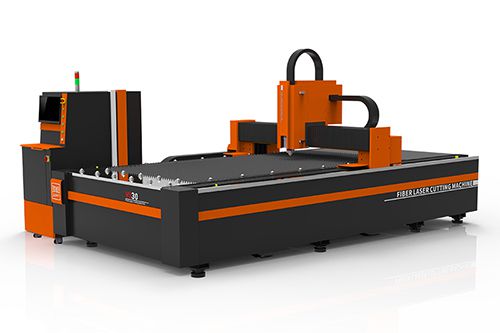

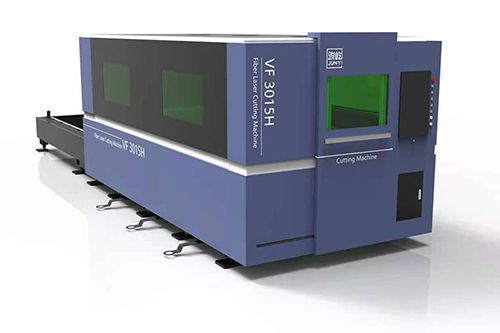

Fiber laser cutting machine can play a vital role in improving quality and shortening production cycle for kitchenware manufacturing. In contrast to traditional metal processing method using CNC punch press in combination with polishing, shearing, bending and molding processes, metal laser cutting machine eliminates the need for molds, can help kitchenware manufacturers improve their processing efficiency and lower operating cost.

- Non-contact cutting method enables user to fabricate metal parts with no distortion, and provides high cutting speed without dust generation.

- Metal laser cutting machine is perfect for large batch production due to its high processing precision and low operating cost.

- High flexibility of laser cutter makes it versatile for processing profiled parts of kitchenware. All you need is to simply import design cutting graphics to the control system and set the cutting parameters. The laser cutting machine can offer fast cutting and smooth cut edge.

Fiber laser cutting machines manufactured by JUNYI can be applied in a multitude of industries. With the proven features of stable performance and high safety certified in accordance with European CE standards, our fiber laser cutting machines can be used not only for kitchenware manufacturing, but also in electronics, machinery and hardware industries.