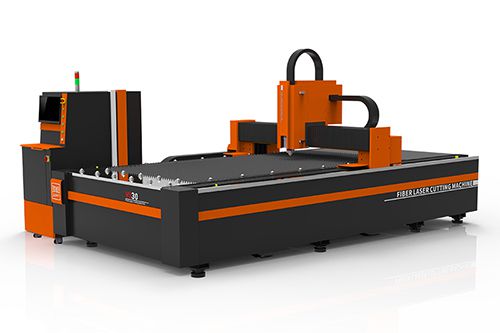

Having regard to the high speed motion requirements, our laser machine is generally designed and constructed with gantry type welded structure. Two-time aging treatment ensures that the machine bed stays high precision and stability after long-time operation, and has a good rigidity that can withstand higher speed and acceleration.

The machine bed of our laser equipment is welded using CO2 gas shielded welding technique, which is the most important ferrous metal welding process known for its features of stable welding process, minimal weld spatter without internal defects.

Ultra-large gas fired annealing furnace is used for stress relieving of several machine beds simultaneously, thus aiming at improving wear resistance and prolonging service life of the machine bed. The annealing furnace is kept at constant temperature of 600ºC, and electronic temperature monitoring system helps completely eliminate the residual stress generated by welding process.

Roughing refers to quickly remove bulk amount of excess materials from workpiece. During rough machining, high feed rate and depth of cut are employed to obtain the highest possible level of material removal rate.

It is a vibrating method to eliminate the internal residual stress in structures. During the vibration process, a small amount of plastic deformation occurs when the stress (vector sum of the internal residual stress and the additional vibration stress) exceeds a metal's yield strength, thus resulting in residual stress relaxation and reduction.

By placing machine bed at outdoor condition for over one month, the thermal stress caused by repeated processing of machine bed can be removed, therefore achieving internal residual stress relaxation, stable size precision, enhanced anti-deformation and high stability of machine bed.

CNC five-sided machining center is adopted for fine machining of guide rail, rack and pinion and other precision parts to ensure the cutting precision of our laser cutting machines.

| Machine | Quantity | Positioning accuracy | Manufacturer |

| Gantry Machining Center 2040 | 1 | 0.01 | Haitian Precision |

| Gantry Machining Center 3080 | 1 | 0.01 | Haitian Precision |

| Vertical Machining Center 60450 | 1 | 0.01 | PRATIC CNC |

| Vertical Machining Center | 5 | 0.003 | Guosheng |