With the improvement of living standards, more and more people become aware of healthy lifestyles. Exercisers are a growing consumer group leading to a business opportunity for fitness equipment manufacturers. To follow the given situation and market needs, most manufacturers strive for heavy investment in technology innovation and production process improvement to stand out from their competitors with premium product quality.

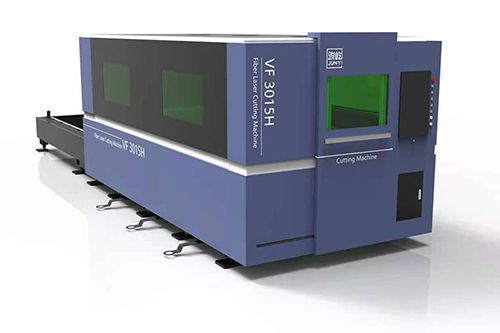

As an advanced way in metal working process, laser cutting had also been widely applied in the field of fitness equipment. Unlike conventional metal tube cutting process requiring loading, unloading, bending, mold changing and other steps, laser cutting machine can provide high efficiency cutting process to produce better quality workpiece, without the need for these time-consuming steps.

- High precision: one of the main shortcomings of conventional tube cutting method is inconsistent length of different cut sections, which is caused by manual operation. Laser tube cutting machine adopts same chuck clamping system designed by programming software to achieve multi-step processing at one pass, thus guaranteeing high cutting precision.

- High efficiency: laser tube cutting machine is able to cut metal tubes of several meters in length within one minute, which is hundreds of times faster than conventional manual cutting machines, providing high processing efficiency.

- High flexibility: laser tube cutting machine can flexibly process workpieces of various shapes, this allows product designers to design complex product shapes that are unimaginable using conventional cutting method.

- High processability: to cut a tube with length of 6 meters, conventional cutting machine requires very cumbersome clamping tools, while the laser tube cutting machine can easily and rapidly conduct tube positioning, enabling the batch processing of metal tubes.

In the manufacturing process of fitness equipment, such as exercise bikes, treadmills, workout benches, a large number of tube processing is required, so that laser tube cutting machine is more necessary for its high efficiency and high precision features.