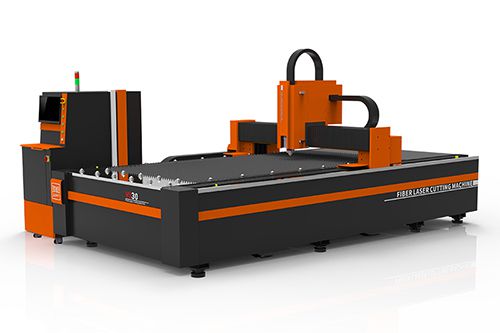

JUNYI's laser equipment is designed and manufactured in accordance with the requirements of GB/T 34380-2017 standard, and we put the standard into practice regarding all aspects including basic parameters, techniques, testing and measuring method, labeling, packaging, transportation and storage.

Testing prior to assembly, the aim of the test is to verify whether the beam processing position tolerance is in compliance with the design values, thus ensuring the quality of laser machines.

Collimator is used to measure the straightness of guide rail to assure the accuracy of every laser machine.

Height measuring device tests and measures the shape and position tolerance of precision parts to guarantee the high precision of workpiece.

Swiss 2D height gauge is utilized for dimensional measurement of geometrical part having either a plane, parallel or cylindrical surface, particularly, internal & external size, depth, height, distance, as well as 1D or 2D measurements.

During the assembling process, our technical professionals skillfully conduct the assembling of guide rail, rack and pinion and other precision parts and ensure the high precision using dial gauge.